Mines look for crushing, screening flexibility in critical minerals

Sandvik Rock Processing’s specialised in-house capabilities deliver tailored and sustainable screening solutions for its mining customers

Service technicians can use reports and analysis on equipment performance to inform and improve their services

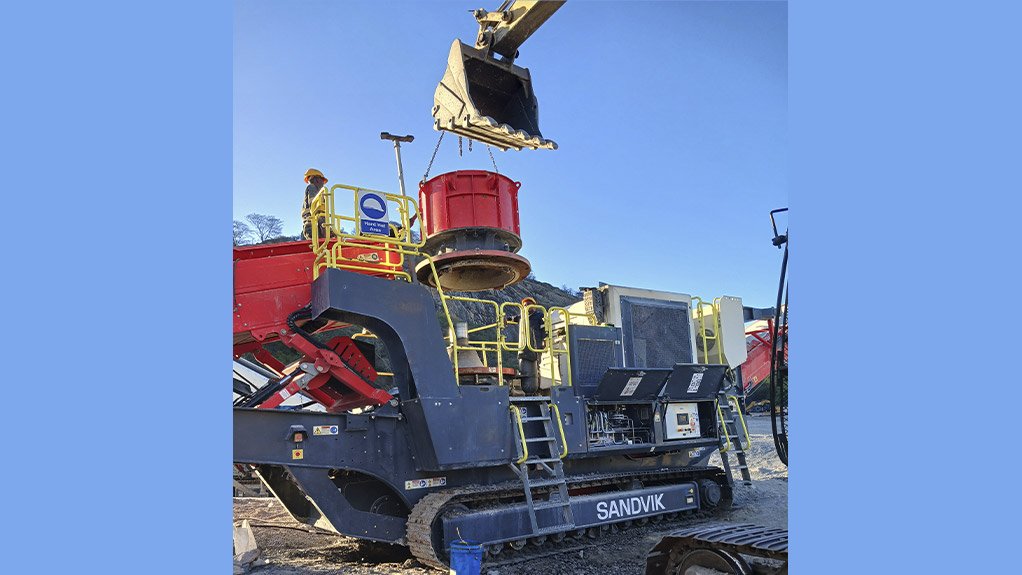

Sandvik’s mobile equipment ensures quick setup and relocation, keeping projects on schedule with minimal downtime

Sandvik Rock Processing’s in-depth technical expertise ensures highly productive and reliable crushing & screening solutions

With demand for most commodities – especially for critical minerals – looking strong, mining projects in Africa want to be able to ramp up crushing and screening capacity quickly to make the best of market changes.

According to Frengelina Mabotja, Business Line Manager Screening Solutions at Sandvik Rock Processing, this means harnessing the power of the latest technologies and digital tools. Mabotja points to the company’s next generation vibrating screens – the SK range – which are designed to meet the highest standards of safety and productivity.

“These screens deliver the lowest total cost of ownership, ensuring that customers achieve maximum uptime and reliability,” she explains.

The successful integration of screens with crushers is another key aspect of Sandvik Rock Processing’s capability, given its extensive range of solutions across the process flow sheet. This allows multiple opportunities for performance improvement, as the company understands each aspect of the flow sheet. Precise integration between all the elements of the plant makes for optimal efficiency in crushing and screening, says Tarynn Yatras, Vice President of Sales Area Africa at Sandvik Rock Processing.

“With our depth of expertise and wide range of offerings, we are able to analyse the performance of crushers and screens in relation to each other, not only the behaviour of each,” she says. “This can unlock value in both throughput and recoveries, with performance being further enhanced by remote monitoring using digital technologies.”

The company has also released an exciting range of crushers that are equipped with automation and digital features that facilitate easy integration into a connected system, says PC Kruger, Business Line Manager for Crushing Solutions at Sandvik Rock Processing. The Sandvik 800 Series cone crushers include the hydraulic Hydroset system, which provides safety and setting-adjustment functions. An electric dump valve releases any hazardous objects from the crusher before any serious damage can be caused.

Yatras points to the value of the company’s ‘Connect the Crusher’ initiative, which is digitally connecting its large installed base of crushers around Africa. This allows equipment’s performance to be carefully monitored, providing data to improve and optimise performance and prevent unplanned downtime.

“Our ever-evolving digital assistant platform SAM is an important element of this technology journey, supporting customers and our own technical teams in achieving operational excellence,” she says. SAM analyses large volumes of performance data using powerful models and algorithms, to make timeous recommendations on which interventions may be necessary.

Article Enquiry

Email Article

Save Article

Feedback

To advertise email advertising@creamermedia.co.za or click here

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation